El Cajón Dam Mexico - Design and Construction

Introduction and Background of El Cajón Dam, Mexico

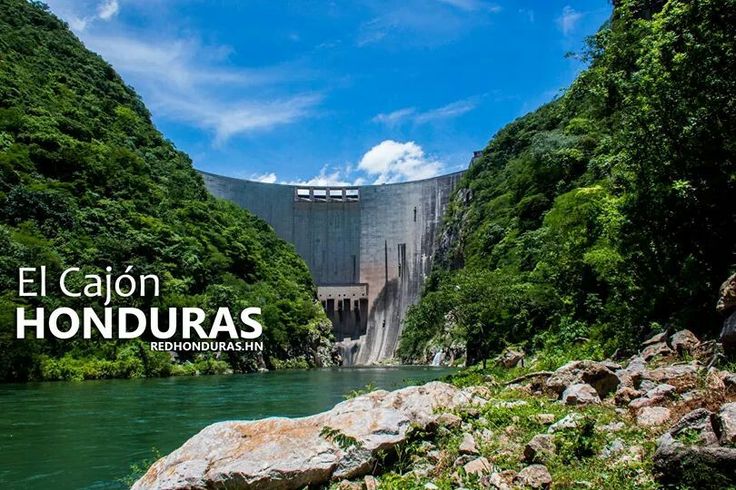

El Cajón dam, Mexico, has a 188 m high concrete-face rockfill dam. The El Cajón Dam is a hydroelectric dam on the Río Grande de Santiago in the Mexican state of Nayarit. Construction began in 2003 and was completed in June 2007. It cost US$800 million to build. It is 640 m (2,100 ft) long and is 178 m (584 ft) high. The reservoir holds approximately 5,000,000,000 m3 (1.8×1011 cu ft) of water, and the generators are capable of producing 750 MW of electricity.

Mexico has one of the biggest dam-building programs in the world. The biggest one is El Cajon Dam, with a height of 620 ft, making it the highest rock-filled dam in the world. It is also to be the world's fastest dam ever built, costing $750 million. Started in 2003, El Cajun finished by 2007. 5000 workers ripped off 12 Million Cubic Yards of rock from the surrounding mountain, working day and night. 11000 tons of dynamite were used (roughly the force of half an atomic bomb) for blasting rocky mountains. Each explosion yielded 10000 cubic yards of rock. The larger rocks were used for facing the dam wall, and the smaller ones for use in concrete as aggregates.

Working Mechanism

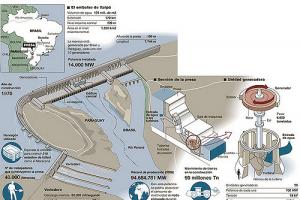

A dam is two things: above the earth is a gigantic wall holding back large volumes of water, and below (5:35), huge tunnels carrying a massive amount of water below the dam into the electricity generating turbines. At the base of each turbine is a scroll case that funnels (5:48) the water onto the turbine blades. The 200-ton scroll case had to be placed onto a concrete base using cranes from above. This required pinpoint accuracy, without which the concrete base or the turbine could have been damaged. These cases were so heavy that they had to be built on site.

Rings - Use and Applications

To strengthen the dam tunnels, pre-fabricated steel rings were designed and installed. The center one was the most critical as it was in the bend of the tunnel, as well as if it was installed properly in its place, all the rest of the rings would fit in perfectly with it. The key ring was designed to fit the bend in the tunnel, but its weight of more than 40 tons posed the problem of managing it and aligning it inside the bend through strings pulled from huge cranes. It was a real engineering challenge.

Even before installation of the rings, procurement of the rings to the construction site was also a tricky situation. The size of the ring was too big for the narrow road leading to the dam site. A longer route was taken to by-pass the narrower one.

Project Director General Salvador Del Pozzo Mastachi - Federico Schroeder Site Project Manager

The spillway of the dam was constructed using 360,000 tons of concrete. The concrete was prepared using ice crushings to prevent it from setting to quickly and cracking in the Mexican heat.