Gradation Of Aggregates | Types of Aggregate Grading

Gradation of Aggregates

Definition

The particle size distribution of an aggregate as determined by sieve analysis is termed as gradation of aggregates. If all the particles of an aggregate are of uniform size, the compacted mass will contain more voids whereas aggregate comprising particles of various sizes will give a mass with lesser voids. The particle size distribution of a mass of aggregate should be such that the smaller particles fill the voids between the larger particles. The proper grading of an aggregate produces dense concrete and needs less quantity of fine aggregate and cement waste, therefore, coarse and fine aggregates must be well graded to produce quality concrete.

Grading limits and maximum aggregate size are specified because these properties affect the amount of aggregate used as well as cement and water requirements, workability, pumpability, and durability of concrete. In general, if the water-cement ratio is chosen correctly, a wide range of grading can be used without a major effect on strength.

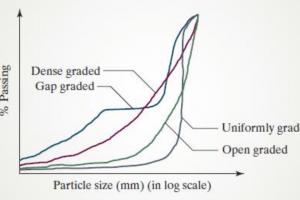

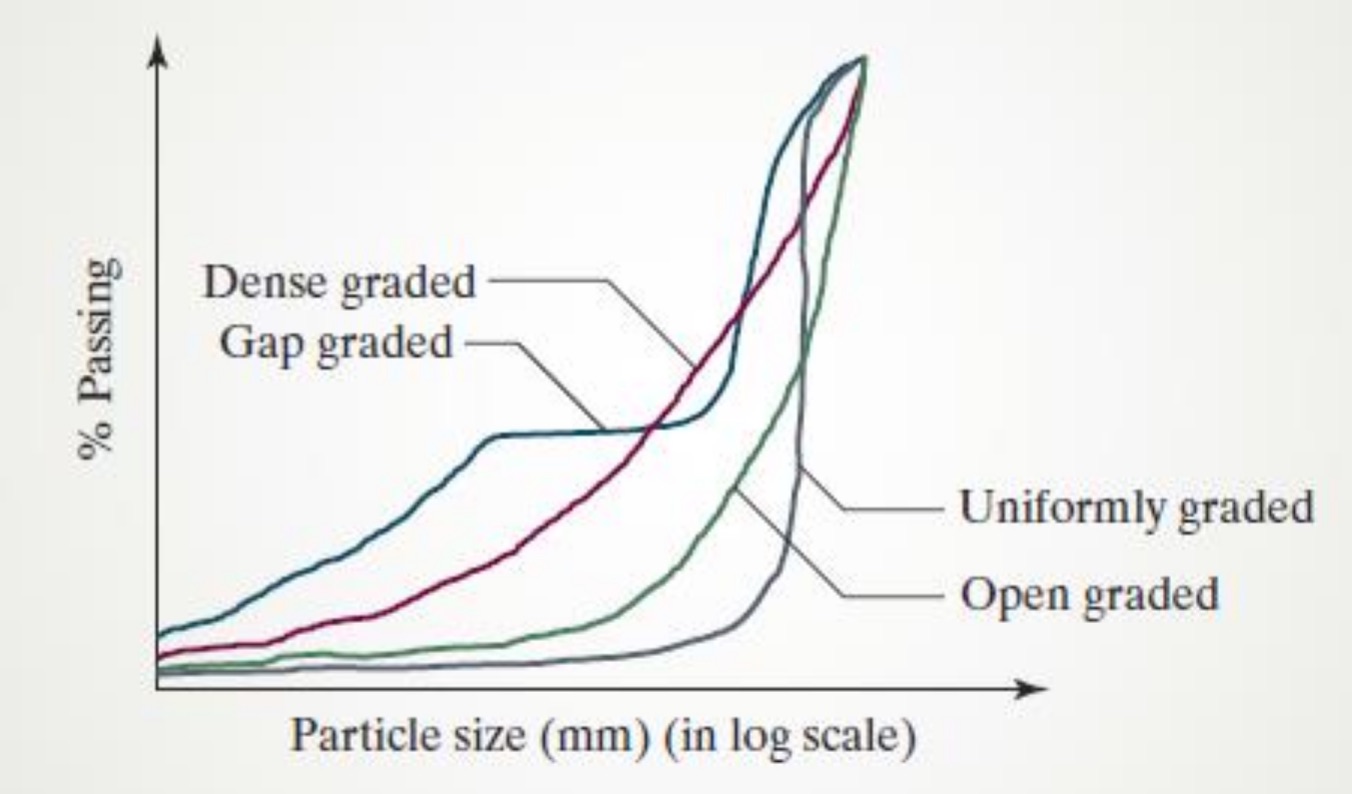

The Grading Curve of Aggregates

The grading of aggregates is represented in the form of a curve or an S-CURVE. The curve showing the cumulative percentages of the material passing the sieves represented on the ordinate with the sieve openings to the logarithmic scale represented on the abscissa is termed as Grading Curve. The grading curve for a particular sample indicates whether the grading of a given sample conforms to that specified, or whether it is too coarse too fine, or deficient in a particular size.

Types of Grading of Aggregates

- Dense- or well-graded aggregate – Has gradation close to the FWHA maximum density grading curve.

- Gap-graded aggregate – Has only a small percentage of particles in the mid-size range.

- Uniformly graded aggregate – Composed mostly of particles of the same size.

- Open-graded aggregate – Contains only a small percentage of small-size particles.

UNIFORM GRADED AGGREGATE

It refers to a gradation that contains most of the particles in a very narrow size range. In essence, all the particles are the same size. The curve is steep and only occupies the narrow size range specified.

- Narrow range of sizes.

- Grain-to-grain contact.

- High void content.

- High permeability.

- Low stability.

- Difficult to compact.

OPEN-GRADED AGGREGATE

In this type of gradation of aggregates, only a small percentage of aggregate particles are in the small range. This results in more air voids because there are not enough small particles to fill in the voids between the larger particles. The curve is near vertical in the mid-size range, and flat and near-zero in the small-size range.

GAP GRADED AGGREGATE

Gap-graded aggregate contains only a small percentage of aggregate particles in the mid-size range. The curve is flat in the mid-size range. Some PCC mix designs use gap-graded aggregate to provide a more economical mix since less sand can be used for a given workability. When gap-graded aggregate is specified, certain particle sizes of aggregate are omitted from the size continuum. Gap-graded aggregates are used to obtain uniform textures in exposed aggregate concrete. Close control of mixed proportions is necessary to avoid segregation.

- Missing middle sizes.

- No grain-to-grain contact.

- Moderate void content.

- Moderate permeability.

- Low stability.

- Easy to compact.

DENSE GRADED AGGREGATE

A dense gradation refers to a sample that is approximately of equal amounts of various sizes of aggregate. By having a dense gradation, most of the air voids between the materials are filled with particles. A dense gradation will result in an

even curve on the gradation graph.

- Wide range of sizes.

- Grain-to-grain contact.

- Low void content.

- Low permeability.

- High stability.

- Difficult to compact.

Dense Graded Aggregate (DGA) is a type of construction material used in the field of civil engineering and road construction. It is a combination of various sizes of crushed stone, gravel, and sand mixed to form a dense and well-graded aggregate. DGA is commonly used as a foundational material in the construction of roads, highways, and various other infrastructure projects. Here are some key characteristics and uses of Dense Graded Aggregate:

Particle Sizes: DGA is composed of a mixture of different particle sizes. These particles range from fine sand to relatively large pieces of crushed stone or gravel. The sizes are carefully selected to achieve a well-graded mix, meaning that there is a balance between the different sizes, allowing for optimal compaction and load-bearing capacity.

CompactionOne of the primary advantages of DGA is its ability to be compacted effectively. When properly compacted, it becomes a dense and solid material that can provide a stable foundation for the construction of roads and pavements. This compaction minimizes voids and ensures load-bearing capacity.

Load-Bearing Capacity DGA is known for its excellent load-bearing capacity, making it suitable for use in areas where heavy traffic loads are expected, such as highways and airport runways. The well-graded composition helps distribute loads evenly and reduces settling or rutting.

Drainage: DGA also offers good drainage properties. The mixture of various particle sizes allows water to flow through the material, preventing the accumulation of water on the road surface and minimizing the potential for erosion and damage.

Stability: DGA provides a stable and level surface, reducing the need for frequent maintenance and repairs. It helps prevent the development of potholes, cracks, and other surface deformities commonly associated with roadways.

Versatility: Dense Graded Aggregate can be used in various construction applications beyond road construction. It is also employed in building foundations, and parking lots, and as a base material for sports fields and landscaping projects.

Local Availability: The specific types of crushed stone and gravel used in DGA may vary depending on regional availability and geological characteristics. This ensures that DGA can be produced using locally sourced materials, which can be cost-effective and environmentally friendly.