Methods for Non Destructive Testing of Concrete

Non destructive testing of concrete can be defined as the test method used to examine the properties of concrete used in the actual structure. These test methods can also be said as in-situ tests or in-place tests. Traditionally these tests are said to be as the non-destructive test although some minor damage to the structure may be involved. An important feature of non-destructive test is that the place where test is done can be used for re-testing. The use of non-destructive tests has increased the safety level of construction and also helps in improving the scheduling of construction. All this increases the speed of construction besides keeping the economy of construction in considerable limits.

Definition:

These tests can be categorized in two parts:

- Tests used to determine the strength of concrete

- Tests used to determine the other characteristics of concrete like voids, cracks etc

Non destructive tests are the representation of relation between the property of structure which is being tested and the strength of test specimen. These tests are usually done in case of disputes between the parties which are involved in construction of any type of structure. Clients usually ask to conduct the test of strength of concrete which is being used in the structure.

The most common tests which are usually conducted are:

Rebound Hammer Test

It is one of the oldest non destructive test. This test is widely used because of its economical procedure. It is used to evaluate the surface hardness of concrete.

The rebound hammer is a surface hardness tester for which an empirical correlation has been established between strength and rebound number. Schmidt hammer, which weighs about 4 lb (1.8 kg) is used for this testing purpose as it incorporates the rebound principle for testing of concrete. The hammer is forced against the surface of the concrete by the spring and the distance of rebound is measured on a scale. The test surface can be horizontal, vertical or at any angle but the instrument must be calibrated in this position.

Calibration can be done with cylinders (6 by 12 in., 15 by 30 cm) of the same cement and aggregate as will be used on the job. The cylinders are capped and firmly held in a compression machine. Several readings are taken, well distributed and reproducible, the average representing the rebound number for the cylinder. This procedure is repeated with several cylinders, after which compressive strengths are obtained.

Penetration Resistance Test

In this test resistance to the penetration of steel rod in the concrete is used as the strength value

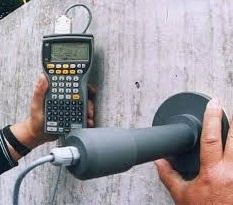

Ultrasonic Pulse Velocity Test

This test has automatic program apparatus. Apparatus is just placed on specimen. The waves pass through the specimen. Time taken by waves to reach from one end of specimen to other is considered to be the strength of specimen. Less the time taken, weaker will be the specimen and vice versa).

It measures the time of travel of an ultrasonic pulse passing through the concrete. The fundamental design features of all commercially available units are very similar, consisting of a pulse generator and a pulse receiver. Pulses are generated by shock-exciting piezo-electric crystals, with similar crystals used in the receiver. The time taken for the pulse to pass through the concrete is measured by electronic measuring circuits.

Ultrasonic pulse velocity tests have a great potential for concrete control, particularly for establishing uniformity and detecting cracks or defects. Its use for predicting strength is much more limited, owing to the large number at variables affecting the relation between strength and pulse velocity.

Pull out Test

This test measure the strength of specimen by means of special tension jacks that are usually used to be inserted in test specimen.

A pull-out test measures, with a special ram, the force required to pull from the concrete a specially shaped steel rod whose enlarged end has been cast into the concrete to a depth of 3 in. (7.6 cm). The concrete is simultaneously in tension and in shear, but the force required to pull the concrete out can be related to its compressive strength. The pull-out technique can thus measure quantitatively the in-situ strength of concrete when proper correlations have been made.