Decay & Preservation of Wood & Timber

![]() Watch a Video on Presentation on Wood Preservation

Watch a Video on Presentation on Wood Preservation

Decay of Wood & Timber:

The principal destroyers of wood are decay, caused by fungus, and attack by a number of animal organisms of which termites, carpenter ants, grubs of a wide variety of beetles, teredo, and limnoria are the principal offenders. In addition, fire annually causes widespread destruction of wood structures. Decay will not occur if wood is kept well ventilated and air-dry or, conversely, if it is kept continuously submerged so that air is excluded.

Most termites in the United States are subterranean and require contact with the soil. The drywood and dampwood termites found along the southern fringes of the country and along the west coast, however, do not require direct soil contact and are more difficult to control. Teredo, limnoria, and other water-borne wood destroyers are found only in salt or brackish waters. Various wood species vary in natural durability and resistance to decay and insect attack. The sapwood of all species is relatively vulnerable; only the heart wood can be considered to be resistant.

Wood Preservation & Wood Preservatives:

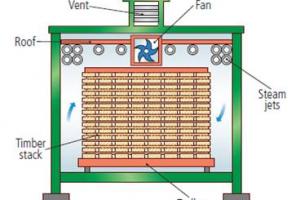

Wood preservation protecting wood, wood products or timbers from deterioration, decomposition or damage due to pest attacks through application of chemical substances. Wood is usually deteriorated by fungi (white rot, brown rot, dry rot, soft rot fungi), insects (termites, beetles, carpenter ants), marine borers (molluscans, crustaceans), and a host of other agents. No single preservative is available which can meet all desirable requirements. Wood preservatives may be oil-borne, water-based or a mixture of different substances. Creosote and pentachlorophenol (PCP) are the organic oil-based preservatives, earlier used for treating of wood poles, piles and railway sleepers in Bangladesh. Nowadays creosote is used only for railway sleepers. Chromated copper arsenate type C (CCA-C) is considered as effective inorganic water-based preservative and is being used for treating electric wood poles, anchor logs and corsairs in Bangladesh.

Chromated copper boron (CCB) is another water-borne preservative, used for indoor use such as for electric meter boards, wooden packings, doors and windows, furniture etc. The third type is a preservative paste, formulated by mixing the oil-borne and water-borne types, such as heavy creosoted boron (HCB). The life of preservative-treated timber products depends on penetration, retention and degree of fixation of preservatives used. The penetration and retention of a preservative, however, depends on the preservation method. The different methods being used in Bangladesh include washing and coating; brushing, spraying and dipping; soaking; Boucherie process; hot and cold bath process; diffusion process; and pressure process. The full cell pressure process is the best for the highest penetration and retention of preservative and is being commercially followed in Bangladesh. In this process air inside the wood is removed by initial vacuum and then empty cells of woods are filled up with preservative chemical by applying pressure on preservative solution. In Bangladesh fixative type of preservative, such as CCA-C is used for ground and water contact timber products and CCB is preferred for indoor use including hardwood and bamboo.

For all practical purposes only a few native species are truly immune to fungal deterioration, and then, as stated earlier, only the heartwood portion of the wood is decay-resistant. Availability and economy usually dictate that where decay resistance is required, preservative treatment is a must. Any structural component that is in contact with the ground, subject to periodic wetting (leakage or rain), or in a high-relative-humidity atmosphere for extended time periods, may be expected to decay. There are several preservatives available; degree of exposure and the use of the member will indicate which specific preservative to use. In all cases a pressure treatment is required; dip treating, soaking, or painting the surface with a preservative solution are only temporary deterrents at best and are not recommended where structural integrity is required. Creosote, one of the oldest and most effective treatments, is used primarily for treating utility poles and marine piling. It is an oilborne preservative of high toxicity and is not recommended where human contact is anticipated.

A number of arsenic containing treatments are commonly used. CCA (chromated copper arsenate) is used with dimension lumber, particularly with southern pine, and ACA (ammoniacal copper arsenate) is also commonly used. Both CCA and ACA are waterborne preservatives that are pressure-impregnated into dry (below fsp) lumber; the chemicals become permanently bonded to the wood as the wood becomes redried after treatment. It is very important to know that until the wood has become dry again after treatment, it is dangerous to handle. Resawn wood that is wet on the inside of the piece, even if it appears dry on the outside, can produce arsenic poisoning. It is also important to know that even under high impregnation pressures, the depth of penetration of the preservative into the wood may be incomplete. Resawing may expose untreated wood to decay; treatment after cutting or boring members to final size is recommended. CCA and ACA treatments are commonly used for foundations, decks, and greenhouses. Dry CCA- and ACA-treated lumber is approved for human contact use.

Under no circumstances are wood scraps of CCA- or ACA-treated wood to be burned in the open air; this will ultimately release poisonous arsenic and chromium compounds into the air. Borate compounds are effective wood preservatives and are economical and nontoxic to humans and animals. Unfortunately, they also leach out of the wood rather readily when subjected to rain or wet conditions. Research on these and other compounds may result in a new family of leach-resistant, nontoxic-to-humans preservatives for wood in the future. Preservative-treated structural lumber is available in several grades, depending upon intended use and retention level.