Secondary Biological Wastewater Treatment Process

1. Objectives of Secondary Treatment of waste water

Main objective

The main objective of secondary treatment: To remove most of the fine suspended and dissolved degradable organic matter that remains after primary treatment, so that the effluent may be rendered suitable for discharge. Conventional secondary treatment can reduce the BOD's to below 20mg/l and Suspended Solids to below 30mg/l which is acceptable in many cases.

Second objective

The second objective of secondary treatment: The reduction of ammonia toxicity and nitrification oxygen demand in the stream. This is achieved by oxidation of most of the ammonia to nitrate during treatment (nitrification).

2. Nitrification:

Means the oxidation of ammonia to nitrate. Nitrification is possible with aerobic biological processes. If they are operated at low organic load rates-hence the units must be large than those which would be required for oxidation of carbonaceous matter alone.

- Conventional sedimentation the major process in primary wastewater treatment, normally removes 60 to 70 % of suspended solids matter containing 30% to 40% of the BOD present in municipal wastewater, leaving 150 to 200 mg/ l of BOD's and about 100mg/l SS in the primary effluent.

- Discharge or effluent of this quality with exceeding the assimilative capacity of the receiving the assimilative capacity of the receiving environment is only possible where very large volumes of water are available for delectation or where the effluent may be irrigated over a large land area.

- For discharge to inland streams or lakes, a considerably higher quality is necessary. Assimilative capacity of O2 in H2O = 9mg/l not less then 2mg/l.

Biological Wastewater Treatment Processes

- Aerobic biological processed

- Anaerobic biological processed

- Facultative biological processed

1. Aerobic Biological Processes

Are those where sufficed amount of dissolved oxygen is required into the wastewater to sustain aerobic action, as one of the major polluting effects of wastewater on streams results form the depletion of dissolved oxygen by the action of aerobic organisms in degrading the organic content of the waste. Practical aerobic biological treatment processes seek to to this, within the constraints of available land area and economic resources available to construct and operate treatment works.

2. Anaerobic Biological Processes

Are those where micro-organisms oxidize organic matter in the completed absence of dissolved oxygen. The micro-organisms take oxygen form inorganic salts which contain bound oxygen (Nitrate NO3, Sulphate So42-, Phosphate PO42-). This mode of operation is termed as anaerobic processes. Sufficiently fore dissolved oxygen is either physically difficult or economically impracticable to transfer into the wastewater to sustain aerobic action to biodegrade strong organic wastes.

Aerobic Biological Treatment Processes

There are five types of aerobic biological treatment processes used to treat municipal sewage

- Tricking filters

- Rotating biological contactors (filter)

- Activated sludge.

- Oxidization ponds.

- Aerated lagoons (used for pre treat ion industrial effluent)

Trickling Filter

Introduction to trickling filter system:

It is the most common attached growth process. The trickling filter is like a circular well having depth up to 2 meter filled with granular media like stone, plastic sheets and redwood, slag, slate. The first tricking filter was placed in operation in England in 1893. the concept of a tricking filter was grew form the of contact frets which were water tight basins filled with broken stones. The limitation the contact filters included a relatively.

- Wastewater is distributed over top area of vessel containing non-submerged packing material;

- Historically, rock was used with typical depths 1.25‐ 2 m

- Modern trickling filters 5 to 10 m and filled with plastic packing material for biofilm attachment;

- 90‐95% of volume in tower consists of void space;

- Air circulation in void space provides oxygen for microorganisms growing as attached biofilm;

- Excess biomass sloughs from attached growth periodically and clarification is required for liquid/solids separation

- High incidence of clogging,

- The long retention time (a typical cycle required 12 hours, 6 hours for operation and 6 hours for resting) and relatively

- Low loading rate. life cycle/ biological circle of bacteria: 20-30 mints. The tricking filter itself consists of a bed of coarse material, such as stones, slates or plastic materials (media) over which wastewater is applied. Because the micro-organisms that biodegrade the waste form a film on the media this process is known as an attached growth process.

Tricking filters have been a popular biological treatment processes the must widely used design for many years are:

Design diameter of Rock filters = 60m (2007t) and for Rock size Design diameter = 25 to 100mm

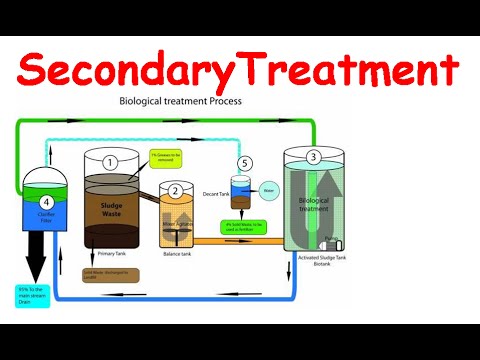

Activated Sludge Process

- It involves production of activated mass of microorganisms capable of stabilizing waste under aerobic conditions;

- In aeration tank, contact time is provided for mixing and aerating influent wastewater with microbial suspension, generally referred to mixed liquor suspended solids (MLSS) or mixed liquor volatile suspended solids (MLVSS)

- Mixed liquor than flows to clarifier where microbial suspension is settled and thickened;

- Settled biomass (activated sludge) is returned to aeration tank to continue biodegradation of influent;

- Portion of thickened solids is removed daily or periodically as process produces excess biomass;

- Formation of floc particles, ranging in size from 50 to 200 μm, removed by gravity settling, leaving relatively clear liquid as treated effluent;

- Typically 99% of suspended solids removed by clarification step;

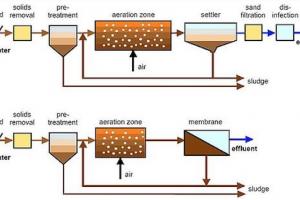

Biological Treatment systems

- Attached growth processes

- Suspended growth processes

- Dual (hybrid) biological treatment processes.

Attached growth process

- Microorganisms responsible for conversion of organic material or nutrients are attached to an inert packing material;

- Organic material and nutrients are removed from wastewater flowing past attached growth also known as biofilm

- Packing materials used in attached growth processes include rock, gravel, slag, sand, redwood and wide range of plastic and other synthetic materials

Suspended Growth (SG) Processes

- Microorganisms responsible for treatment are maintained in liquid suspension by appropriate mixing methods;

- Many SG processes are operated with positive dissolved oxygen concentration;

- Most common SG process is activated sludge process