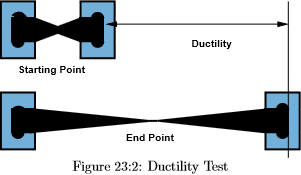

To Perform Ductility Test on Bitumen

A ductility test is conducted to determine the amount of bitumen that will stretch at a temperature below its softening point. A briquette having a cross-sectional area of 1 in2 is placed in a tester at 77 °F. Ductility values range from 0 to over 150 depending on the type of bitumen.

The ductility test is a standard method used to evaluate the flexibility and elongation properties of bitumen. It measures the distance in centimeters to which a standard briquette of bitumen can be stretched before it breaks. The test provides valuable information about the ability of bitumen to withstand deformation under varying temperature conditions, as well as its suitability for different applications such as road construction. By assessing the ductility of bitumen, engineers can make informed decisions regarding the selection and application of this crucial material in civil engineering projects.

APPARATUS:

- Penetration Apparatus

- Needle

- Container

- Water Bath

- Thermometer for Water Bath

- Stop Watch

The procedure of the Ductility Test on Bitumen:

Ductility is the property of bitumen that permits it to undergo great deformation or elongation.  Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking. The dimension of the briquette thus formed is exactly 1 cm square. The bitumen sample is heated and poured into the mold assembly and placed on a plate. These samples with molds are cooled in the air and then in a water bath at 27 °C temperature. The excess bitumen is cut and the surface is leveled using a hot knife. Then the mold with the assembly containing the sample is kept in a water bath of the ductility machine for about 90 minutes. The sides of the molds are removed, the clips are hooked to the machine, and the device is operated. The distance up to the point of breaking of the thread is the ductility value reported in cm. The ductility value is affected by factors such as pouring temperature, test temperature, rate of pulling, etc. A minimum ductility value of 75 cm has been specified by the BIS.

Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking. The dimension of the briquette thus formed is exactly 1 cm square. The bitumen sample is heated and poured into the mold assembly and placed on a plate. These samples with molds are cooled in the air and then in a water bath at 27 °C temperature. The excess bitumen is cut and the surface is leveled using a hot knife. Then the mold with the assembly containing the sample is kept in a water bath of the ductility machine for about 90 minutes. The sides of the molds are removed, the clips are hooked to the machine, and the device is operated. The distance up to the point of breaking of the thread is the ductility value reported in cm. The ductility value is affected by factors such as pouring temperature, test temperature, rate of pulling, etc. A minimum ductility value of 75 cm has been specified by the BIS.

Step-by-Step Procedure of Bitumen Ductility Test

Sample Preparation:

A briquette of bitumen is prepared by pouring molten bitumen into a mold and allowing it to cool and solidify. The dimensions of the briquette typically conform to standard specifications. Heat the bitumen sample in a water bath or oven to bring it to a temperature of 25-30°C above its expected softening point. Prepare briquette molds by coating them with a thin layer of glycerin or petroleum jelly to facilitate the easy removal of the bitumen sample.

Conditioning:

The prepared briquette is typically conditioned at a specified temperature for a specific duration to ensure consistency in the test conditions. Conditioning may involve heating or cooling the sample to simulate the temperature conditions it will experience in the field.

Mounting the Briquette:

The conditioned briquette is then mounted vertically between two clamps in a ductility testing machine. The lower end of the briquette is usually immersed in a water bath to maintain a constant temperature during the test. Place the heated bitumen sample into the mold while ensuring it fills the mold cavity. Allow the sample to cool for a short time in the mold.

Stretching the Briquette:

The clamps move apart at a specified speed, stretching the briquette until it breaks. The rate of separation is typically standardized to ensure consistency across different tests.

Testing Procedure:

Start the machine and apply a constant pulling force to the bitumen sample at a specified rate (usually 50 mm/min). This rate should be maintained throughout the test. The bitumen sample will start to stretch and deform. Measure the extension of the sample continuously until it breaks or the stretched portion becomes too thin to measure accurately.

Recording the Ductility Value:

The distance the briquette stretches before breaking is measured and recorded as the ductility value in centimeters. This value represents the ductility or elongation properties of the bitumen sample. Record the distance (in millimeters) the bitumen sample stretched before it broke or became too thin to measure. This value is the ductility value.

Calculations

The ductility of the bitumen is calculated as the distance the sample stretches before breaking. This value is typically reported in millimeters.

Interpretation of Results of Bitumen Ductility Tests

A longer ductility value indicates that the bitumen is more flexible and can withstand greater deformation before breaking. This property is essential in road construction, as it allows the bitumen to accommodate the movement and stresses that occur in road pavements due to temperature changes and traffic loads. The minimum ductility requirements may vary depending on the specific standards and specifications of the project.

Applications of Bitumen Ductility Tests

Here are some of the key applications of the ductility test for bitumen:

-

Road Construction: Ductility testing helps determine the ability of bitumen to withstand deformation and stretching under varying temperatures and traffic loads. Bitumen with good ductility is preferred for road construction as it can better accommodate the movement and stress experienced by road pavements.

-

Pavement Design: Engineers use the results of ductility tests to select the appropriate grade of bitumen for specific pavement design requirements. Ductility values influence the choice of bitumen for different climate conditions and traffic loads.

-

Crack Resistance: Bitumen with high ductility is more resistant to cracking and can extend the lifespan of road surfaces. It helps reduce the formation of cracks, which can lead to pavement deterioration.

-

Binder for Asphalt Mixes: Bitumen is commonly used as a binder in asphalt mixes. The ductility of bitumen is a critical factor in determining the performance and durability of the asphalt mixture.

-

Roofing and Waterproofing: Bitumen is used in roofing and waterproofing applications to create weather-resistant and waterproof barriers. Ductility is important to ensure the bitumen can be applied and maintained without cracking or losing its sealing properties.

-

Expansion Joints: Bituminous materials with good ductility are used in expansion joints of bridges and other structures to accommodate movement without breaking or deteriorating.

-

Cold Mix Asphalt: Ductility testing can also be used to evaluate bitumen used in cold mix asphalt, which is a more flexible and convenient alternative to traditional hot mix asphalt.

-

Adhesive and Sealant Applications: Bitumen-based adhesives and sealants are used in various construction applications. Ductility is important to ensure that these materials remain flexible and effective over time.

-

Quality Control: Ductility tests are an essential part of quality control in bitumen production and application. Contractors and suppliers use these tests to ensure that the bitumen used in construction projects meets specified requirements and standards.

-

Research and Development: Ductility testing is also valuable in the research and development of new bitumen formulations and products. It helps engineers and scientists understand how changes in bitumen composition affect its ductility and performance.

In all these applications, the ductility of bitumen is a key factor in determining the material's ability to withstand deformation, temperature fluctuations, and the stresses imposed by various structures and traffic loads. It plays a significant role in ensuring the longevity and effectiveness of construction materials and infrastructure.