Laboratory Investigation of Hooke’s Law

Apparatus:

UTM , test specimen, divider, vernier caliper, scale.

Procedure:

-

Prepare the test specimen that is steel bar and find its diameter at tree different places and find its man value.

-

Mark two points 8" a part of 2 ft long steel bar.

-

Insert the bar in jaws for gripping the steel bar and select suitable bar on UTM. Place the steel bar and fix it.

-

Start t machine and start applying load.

-

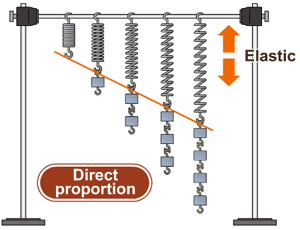

There will be gradual increase in length which will be directly proportional to applied load.

-

During this load application measure change in length at different load, till the steel bar breaks.

-

Find the stress and strain at those points and investigate the law by drawing the graph between stress and strain

| S No | Dia of Bar | Load(Tons) | Elongation | Area of Bar | Stress = Load/Area | Strain= Elongation/Gauge Length |

| 01 | ¾ in | 3.68 | 0 in | 0. 441 in2 | 8.34 Psi | 0 |

| 02 | ¾in | 6.84 | 0 in | 0. 441 in2 | 15.51Psi | 0 |

| 03 | ¾ in | 10.28 | 0 in | 0. 441 in2 | 23.31 Psi | 0 |

| 04 | ¾ in | 10.72 | 1/8 in | 0. 441 in2 | 24.30 Psi | 0.0156 |

| 05 | ¾in | 11.82 | 3/16 in | 0. 441 in2 | 26.80 Psi | 0.0234 |

| 06 | ¾in | 12.04 | ¼ in | 0. 441 in2 | 27.30 Psi | 0.031 |

| 07 | ¾in | 13.04 | 5/16 in | 0. 441 in2 | 29.56 Psi | 0.039 |

| 08 | ¾in | 13.78 | 7/16 in | 0. 441 in2 | 31.24 Psi | 0.054 |

| 09 | ¾in | 14.34 | 9/16 in | 0. 441 in2 | 32.51 Psi | 0.070 |

| 10 | ¾in | 14.88 | 11/16 in | 0. 441 in2 | 33.74 Psi | 0.085 |

| 11 | ½ in | 12.6 (Rupture) | -------------- | 0. 196 in2 | 64.28 Psi | --------------------- |

| 12 | ½ in | 15.86 (Ultimate) | 2 ¼ in | 0. 196 in2 | 80.91 Psi | 0.218 |