Definition and Properties of Emulsified Asphalt

Definition:

A mixture of asphalt cement, water, and emulsifying agent (free-flowing liquid at ordinary temperature). These three constituents are fed simultaneously into a colloid to produce extremely small globules (5-10µ) of asphalt cement, which are suspended in water. The emulsion contains about 50% - 65% bitumen.

Properties of Emulsified Asphalt

- Is graded as rapid setting, medium setting (MS), and slow setting (SS)

- It has advantages in construction, particularly when is used with moist aggregate or in wet weather.

- It doesn't need a solvent to make it liquid and is thus relatively pollution-free

- Has low viscosity at ambient temperature, and it generally can be used without additional heat.

The properties of emulsified asphalt include the following:

1. Grading:

Emulsified asphalt is categorized into different grades based on its setting time. It can be classified as rapid setting, medium setting (MS), or slow setting (SS) depending on the desired application and conditions.

2. Advantages in Construction:

Emulsified asphalt offers several advantages in construction, especially when used with moist aggregate or in wet weather conditions. It allows for better adhesion between the asphalt and aggregate, resulting in improved pavement performance.

3. Pollution-free:

Unlike other asphalt binders, emulsified asphalt does not require a solvent to make it liquid. It is water-based and, therefore, relatively pollution-free. This makes it an environmentally friendly choice for construction projects.

4. Low Viscosity:

Emulsified asphalt has a low viscosity at ambient temperature, which means it flows easily and can be applied without additional heating. This property makes it convenient to use, as it eliminates the need for extensive heating equipment, reducing energy consumption and costs.

5. Versatility:

Emulsified asphalt is a versatile material that can be used for various applications, including surface treatments, tack coats, cold mix asphalt, and soil stabilization. Its flexibility allows for a wide range of uses in different construction scenarios.

It's important to note that the specific properties and characteristics of emulsified asphalt may vary depending on the formulation and additives used in the production process. Different types of emulsifiers and additives can be incorporated to modify the properties of the emulsion, enhancing its performance and compatibility with specific construction requirements.

The slurry seal shall consist of a mixture of an approved emulsified asphalt, mineral aggregate, water, and specified additives, proportioned, mixed, and uniformly spread over a properly prepared surface as directed by the Buyer's Authorized Representative (B.A.R.). The completed slurry seal shall leave a homogeneous mat, adhere firmly to the prepared surface, and have a friction-resistant surface texture throughout its service life.

Emulsified Asphalt Damp Proofing

Emulsified asphalt damp proofing is a method used to protect structures, such as basements and foundation walls, from moisture penetration. It involves the application of a specialized emulsified asphalt material to create a waterproof barrier. The process of emulsified asphalt damp proofing typically involves the following steps:

1. Surface Preparation:

The surface to be treated is cleaned and prepared by removing any loose debris, dirt, or existing coatings. It is essential to have a clean and smooth substrate for proper adhesion of the emulsion.

2. Emulsion Application:

The emulsified asphalt material is applied to the surface using various methods such as spraying, rolling, or brush application. The emulsion is typically a water-based mixture of asphalt binder and an emulsifying agent.

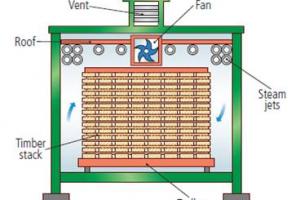

3. Drying and Curing:

After application, the emulsion needs to dry and cure to form a continuous, waterproof barrier. The drying time can vary depending on factors such as ambient temperature, humidity, and the type of emulsion used.

4. Protection and Finishing:

Once the emulsion has dried and cured, it is recommended to protect the surface with a protective coating or covering, such as a waterproofing membrane or protective paint, to provide additional durability and resistance to moisture.

Benefits of Emulsified Asphalt Damp Proofing

Emulsified asphalt damp proofing offers several benefits in moisture protection:

1. Waterproofing:

The emulsified asphalt forms a continuous, impermeable layer that prevents water from seeping through the treated surface. It helps to keep the interior spaces dry and protects the structure from water-related damage.

2. Flexibility:

Emulsified asphalt is known for its flexibility, which allows it to withstand minor movements or cracks in the substrate without compromising its waterproofing capabilities. This flexibility helps to accommodate normal structural movements without developing leaks.

3. Easy Application:

Emulsified asphalt is easy to handle and apply, making it a convenient choice for damp-proofing applications. It can be applied to both horizontal and vertical surfaces, adapting to various project requirements.

Emulsified asphalt damp proofing is commonly used in residential, commercial, and industrial construction projects to provide a cost-effective solution for moisture control and protection. It helps to create a barrier against water intrusion, minimizing the risk of structural damage and potential moisture-related issues.